Calcium Silicate Board

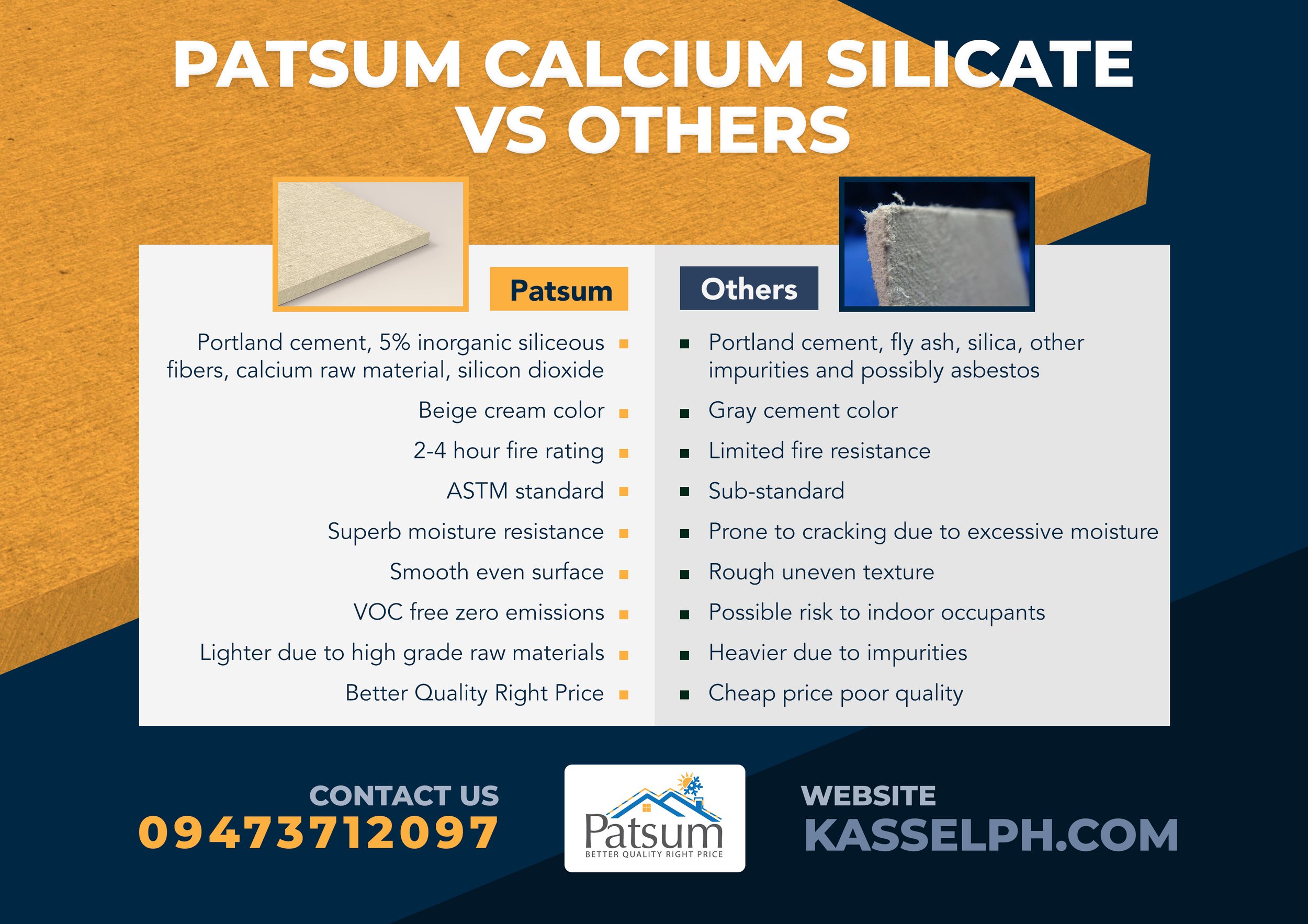

Patsum Calcium Silicate Board is mainly composed of inorganic siliceous high-grade heat-resistant fibers, silicon and calcium raw materials heated by high pressure steam curing resulting in a product that is strong, lightweight and incombustible. The key to producing high-grade calcium silicate board is the ratio and quality of the raw materials together with the expert control of the steam curing process.

Our calcium silicate board is moisture resistant with very small expansion rate. It is immune to vermin and other insects.

Calcium Silicate Board Specifications

Color: Beige - Off White (Not gray cement color)

Density : 1350kg/m3

Dimensions : 1220 x 2440mm

Surface: Smooth

Impact Strength: Heavy duty

Water Permeability: No water formation after 24 hrs

Alkalinity: pH 9

Available in various thickness: 4.5mm, 5mm, 6mm, 9mm, 12mm, 14mm, 16mm, 18mm

Quality Standard: Conform to ASTM C1186

Safety : Non Toxic. No emission of harmful gases under any conditions. Non-asbestos

Temperature: More than 1000°C

Acoustic Properties: 30-80DB

Excellent chemical resistance with high-durability performance

Calcium Silicate Board Applications

Structural Steel Protection

Fire Protection Kitchen Exhaust Duct

HC Fire Tunnel Protection

Fire-Rated Doors

Ceiling and Wall Partitions

Raised Flooring System